YOSHIDA is also known as “the compact company“.

We have embodied the unique designs created by cosmetics brands around the world.

With over half a century of production experience, we continue to deliver our products to the world.

-

-

YK Print (single)

- A pre-decorated film is inserted into the mold. This is a technology that transfers only the decorative portion to the product in the mold at the same time as it is molded. YOSHIDA was the first in the world to develop this technology. Compared to the general method of decorating by printing or painting after molding This can shorten lead times and improve yields. This process can also be applied to the top surface of caps.

-

-

-

-

YK Print(double)

- Two sheets of pre-decorated film are sandwiched inside the mold. This is a technology that transfers only the decorative portion to the product in the mold at the same time as it is molded. If the product is made transparent, two types of decoration are applied to the front and back design can be expressed.

-

-

-

-

YK Hook

- In 1979, we developed the world's first push-button-opening compact case. YK Hook made this possible. At the time, it overturned the common practice of compacts that required two hands to open. This innovative mechanism made it possible to open the case with one hand.

-

-

-

-

Airtight Compact

- Compact case set with excellent airtightness. A highly airtight refill case and a compact case that can be set inside. These products are used by cosmetics brands around the world. (PAT)

-

-

-

-

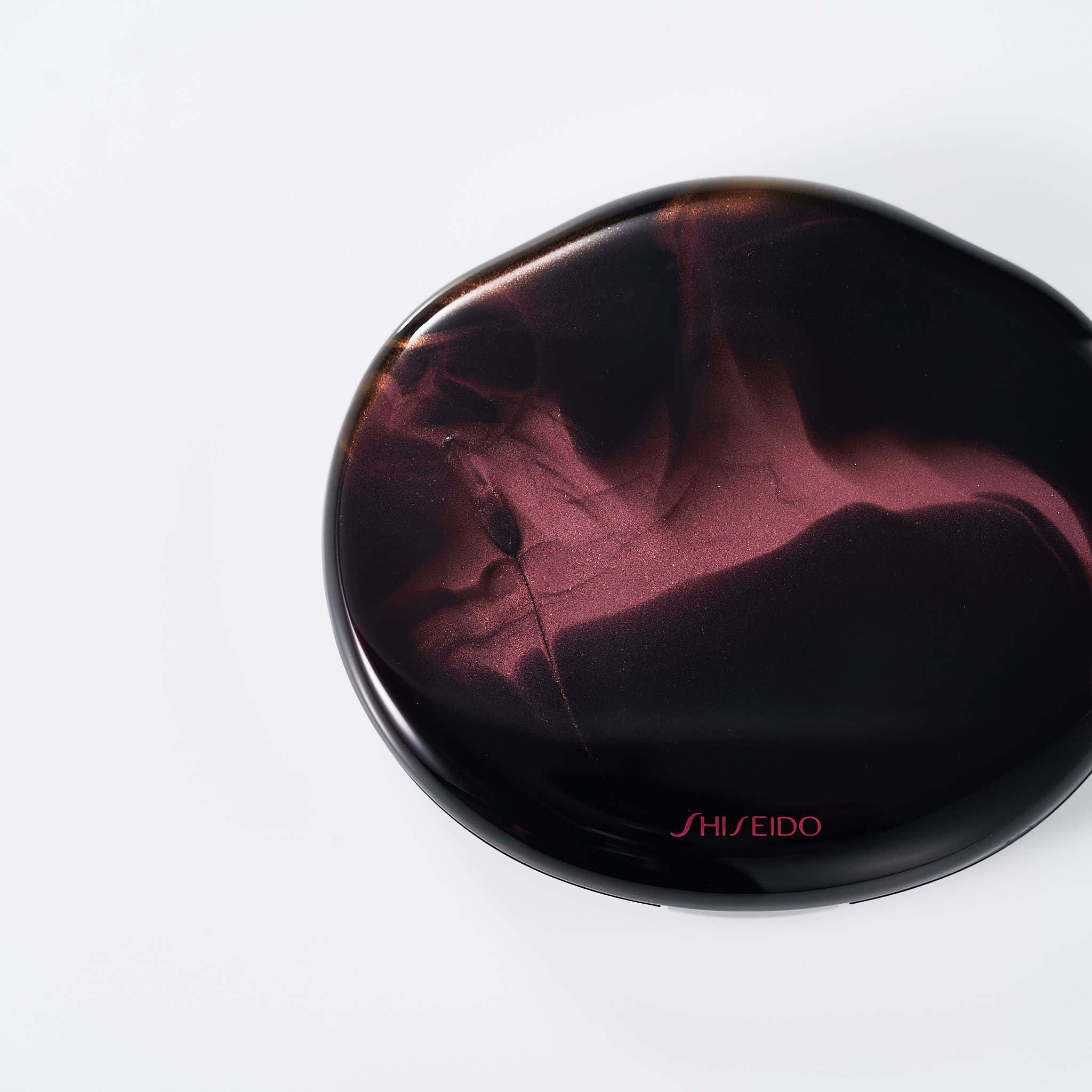

Marble molding

- Using two or more types of plastics of different colors and materials, this is a method of injection molding that simultaneously injects the product into a single mold to create marble-like patterns and meteor shower-like appearances. Furthermore, depending on the design, it is possible to maintain the regularity of the appearance in mass production. This method can be applied to injection molded products in general.

-

-

-

-

YK Metal

- Aluminum sheets are punched out in a die, then simultaneously molded and decorated process that integrates the product into the surface of the product. (PAT) Unlike other metallic texture reproduction processes such as hot stamping or vapor deposition, this process provides a realistic texture. This process can also be applied to caps.

-

-

-

-

Masked mold

- Decorated plastic sheets are formed three-dimensionally with compressed air and insert-molded in the mold. This is a molding process that integrates one piece of plastic with another. This process can also be applied to caps.

-

-

-

-

YK leather

- Leather (synthetic leather) is inserted into the mold. This is a molding process that integrates the plastic with the product. Various looks and textures can be expressed by using this method in combination with mold engraving. This process can also be applied to caps.

-

-

-

-

Sustainable option

- We are also working to reduce the use of petroleum-based plastics through the use of biomass materials, recycled materials, and the blending of discarded plant scraps and inorganic materials. We have a lot of experience in thin-walled, lightweight designs and refillable containers. We can also produce compact containers made of a single material, replacing all glass mirrors and metal hinged pins with plastic.

-

-

YPK_0102.jpg)